News

This is an ad about the making of Djistra

Delivering Engineering, Maintenance and Decommissioning Excellence to Process, Producton and Manufacturing Industries

Pigging is a standard process within the Oil and Gas industry involving the deployment of a specialist cleaning device, known as a Pig, down a process pipeline, using the downstream process pressure to drive the pig to the end of the line. The Pig is then required to be removed to allow the continuation of production of the plant. The Pig positon varies at the end of the pipeline due to the varying pressure and fricton forces encountered in the pipeline during the process

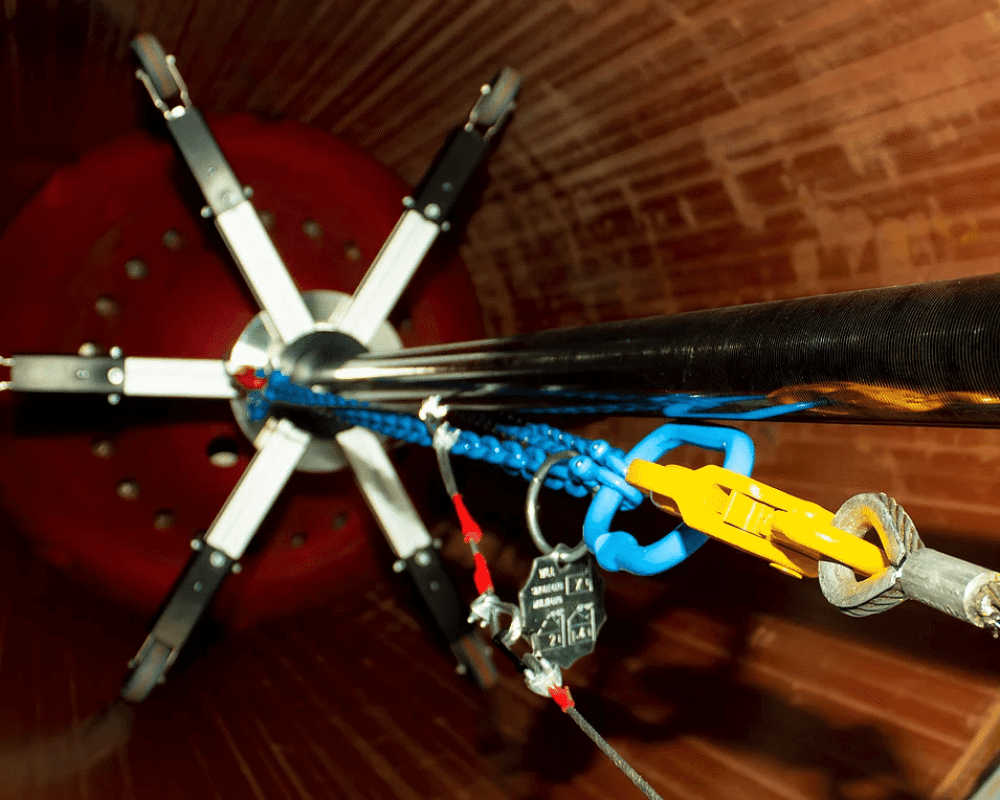

Markon Ashleigh were approached by a customer who were unhappy with the current labour- intensive Pigging process, which used a long reach hook and tirfor to latch and then retract the Pig to the retrieval point and were seeking a safer, more efcient solution Markon Ashleigh therefore, began to develop a modular tool spread that integrates an ATEX Zone 1 pneumatic winch to a receiving cradle for the Pig, which is then coupled to a lightweight, self-supported and centralised long reach grabbing device (adjustable up to 15m), utilising an auto-locking grab at the front of the assembly, which latches to the Pig upon contact with the Pig's latching point, used in tandem with a front-mounted ATEX Zone 1 camera linked to a topside viewing monitor, to provide a feedback loop to the operator, thus reducing manual handling and operating time, to allow the swift return to production as well as improving the ultimate safety of the process. The latching point on the Pig for this project was a wire rope which drove the design of the front grab, however, due to the modular design of the tool spread, only the front grab need be modied to tailor to any different Pig latching point designs.